China OEM Lifting Chain CHINAMFG G43 Mining Welded Heavy Iron Round Lifting Link Black Mining Chain

Product Description

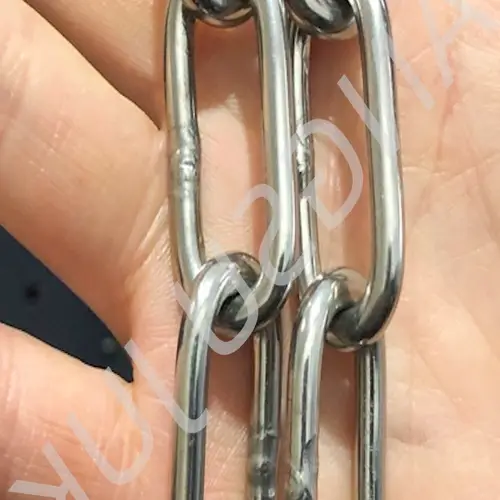

Introducing our high-quality lifting chain, suitable for mining and heavy-duty applications. This chain is made from 20Mn2 alloy steel, ensuring excellent strength and durability. It adheres to the EN818-2 standard and is available in sizes ranging from 6mm to 42mm. Choose from various surface finishes including black, self-colored, and galvanized. With a breaking load capacity of 45-2200 kN, our lifting chain is built to handle heavy loads. It can be packaged in iron drums, wooden cases, or woven bags, and the delivery time is 15-20 working days. See detailed photos below:

| PRDUCT NAME | Grade 80 lifting Chain high strength CHINAMFG chain |

| STHangZhouRD | High quality alloy containing Cr, Ni, Mo |

| Strength grade | G80 |

| PACKING | Plywood reel/plastic reel/plastic drum/gunny bag/iron drum+plywood pallet/iron pallet |

| FINISH | Self-colored, Paint, Black, Galvanized, Yellow. |

| OEM | Accepted. |

| MOQ | 1-5t according to the size you need. |

| Mark | G43, G63, G70, G80 each 20 links or according to your requirements. |

| ADVANTAGE | 1. High and homogen tensile strength |

| 2. Excellent core ductility | |

| 3. Long service life | |

| 4. Safety factor: Min. 4:1 | |

| 5. Do 2.4 times of WLL manufacturing validation strength tensile test. | |

FAQ

-

Are you a factory or a trading company?

We are a factory established in 1993, specializing in producing lifting equipment and rigging hardware. Our wide range of products includes electric hoists, manual hoists, stainless steel hoists, electric winches, hand pallet trucks, manual stackers, lifting chains, lifting hooks, webbing slings, chain rigging slings, and more.

-

Where is your factory located? How can I visit there?

Our factory is located in HangZhou City, ZheJiang Province, China. It is conveniently situated about 1 hour’s drive from ZheJiang. We warmly welcome all clients, whether local or international, to visit us.

-

Can you do OEM?

Yes, we can provide OEM products. We are capable of customizing sizes, packaging, and logos according to your specific requirements.

-

How do you control your quality?

Quality is our top priority. Our factory has a dedicated Quality Control Department that ensures strict quality checking throughout the production and packaging process. We use environmentally-friendly raw materials and employ skilled workers to maintain attention to detail.

-

What are your advantages compared with others?

As an ISO Quality Management System Certificated Factory, we offer the following advantages:

- CE Certification and Assessed Factory

- Over 25 years of experience in rigging production

- Owned factory, ensuring the same quality product at the best price

- Timely delivery with the support of our 5000 square meter warehouse

- Holder of numerous patents in rigging hardware

- A professional trading team with over 10 staff members, providing worry-free and effective communication

At our company, we not only specialize in lifting chains but also supply various other industrial products. Our extensive range includes agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, welded chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We pride ourselves on offering high-quality products, competitive prices, and excellent customer service. Customization of drawings and samples is always welcome.

All the content of this page is from the Internet and is only intended as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are designed to perfectly adapt to the original spare parts. If you need to buy original spare parts, please contact the original factory or supplier.

Performance Characteristics of Welded Chain

Welded chains possess several performance characteristics that make them highly reliable and suitable for various applications. These characteristics include:

1. High Strength: Welded chains are known for their exceptional strength, making them capable of withstanding heavy loads and harsh conditions.

2. Durability: These chains have excellent durability, allowing them to withstand wear and tear, ensuring a longer service life.

3. Flexibility: Welded chains offer flexibility in terms of design and configuration, making them adaptable to different applications and requirements.

4. Resistance to Abrasion: These chains are resistant to abrasion, making them suitable for applications that involve friction and continuous use.

5. Easy Maintenance: Welded chains are relatively easy to maintain, allowing for convenient inspection and lubrication, which helps to extend their lifespan.

Types and Characteristics of Welded Chain

Welded chains are available in various types, each designed to cater to specific applications. Some common types include:

1. Welded Steel Chains: These chains are made of high-grade steel and are widely used in heavy-duty applications due to their strength and durability.

2. Welded Stainless Steel Chains: Stainless steel chains are known for their corrosion resistance, making them ideal for applications in corrosive environments such as marine industries.

3. Welded Alloy Steel Chains: Alloy steel chains are specifically designed to withstand extreme conditions and have high tensile strength.

Advantages of Welded Chain Made of Different Materials

Different materials used in the manufacturing of welded chains offer specific advantages:

1. Steel Chains: Steel chains provide high strength and durability, making them suitable for heavy-load applications.

2. Stainless Steel Chains: Stainless steel chains offer excellent corrosion resistance, making them ideal for applications in environments with high moisture or chemical exposure.

3. Alloy Steel Chains: Alloy steel chains offer exceptional strength and toughness, allowing them to withstand extreme conditions and heavy impacts.

Application of Welded Chain

Welded chains find extensive use in various industries, including:

1. Marine Industry: Welded chains are used for anchoring, mooring, and towing applications in the marine industry due to their durability and corrosion resistance.

2. Construction: Welded chains are commonly used in construction for lifting, pulling, and securing heavy materials and equipment.

3. Agriculture: These chains are employed in agricultural machinery for tasks such as operating conveyors, securing loads, and driving equipment.

4. Transportation: Welded chains play a crucial role in transportation by being used in vehicle towing, cargo handling, and loading systems.

5. Mining: In the mining industry, welded chains are used for hauling and lifting heavy loads, as well as in conveyor systems.

Future Development Trends and Opportunities

The future of welded chain products holds promising possibilities. Some industry development prospects include:

1. Advancements in Material Technology: Continuous research and development in materials used for welded chains can lead to improved strength, durability, and corrosion resistance.

2. Automation and Robotics: The integration of automation and robotics in chain manufacturing processes can enhance productivity and quality control.

3. Sustainable Practices: The adoption of sustainable manufacturing practices, such as recycling and eco-friendly materials, can contribute to a more environmentally conscious industry.

4. Innovative Design: Emphasizing innovative design solutions can lead to chains that are more efficient, lightweight, and versatile.

Choosing a Suitable Welded Chain

When selecting a welded chain, consider the following aspects:

1. Determine Application Requirements: Identify the specific requirements of your application, such as load capacity, environmental conditions, and desired chain functionality.

2. Identify the Type of Chain: Choose the appropriate type of welded chain based on the application’s demands, considering factors like strength, corrosion resistance, and flexibility.

3. Select the Chain Material: Determine the material that best suits the application’s needs, considering characteristics such as strength, corrosion resistance, and temperature tolerance.

4. Consider the Chain Dimensions: Ensure that the chosen chain has the correct dimensions, including pitch, width, and thickness, to ensure proper fit and performance.

5. Check Compatibility with Sprockets: Verify that the selected chain is compatible with the sprockets or wheels it will be used with, ensuring smooth operation and optimal performance.

In conclusion, welded chains are essential components in various industries due to their high strength, durability, and adaptability. Choosing the right welded chain involves considering application requirements, identifying the appropriate type and material, checking dimensions, and ensuring compatibility. As the industry continues to evolve, embracing technological advancements, sustainability, and innovative design will shape the future of welded chain products.

Author: Dream